常州江苏大学工程技术研究院

Changzhou Engineering and Technology Institute of Jiangsu University

Welcome to Changzhou Engineering and Technology Institute of Jiangsu University!

Additive manufacturing technology, especially metal additive manufacturing technology, is regarded as a subversive advanced manufacturing technology in the 21st century. At present, additive manufacturing equipment and technology are developing rapidly in our country, but the additive manufacturing materials are relatively lagging behind.

The powder core wire material in this work has the advantages of both powder and solid wire, and at the same time avoids their shortcomings. It has the following outstanding characteristics.

(1) It can give full play to the diversity of the marketable powders, and reasonably prepare the metal skin and elemental or alloying powders, which can easily obtain the target alloy components of additive manufacturing. Moreover, it can also add various functional powders such as rare earth powder, nano powder, wear-resistant powder, etc., breaking through the limitation of existing additive manufacturing materials and easy to form serialized products.

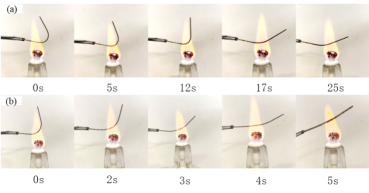

(2) Remarkable burn resistance; The "coating powder" with high melting point coating and its unique "gradient heat transfer effect" can inhibit the uneven burning of alloying elements in the additive manufacturing process, especially to ensure the effectiveness of trace modified elements, so as to ensure the accuracy of additive manufacturing components.

(3) Strong engineering adaptability; Without the restrictions of powder sphericity and particle size on the fluidity of powder delivery and the uniformity of powder laying, the additive manufacturing components have good organizational uniformity, and the additive manufacturing process can be properly adjusted to obtain no obvious stratification, no defects and dense metal solid components.

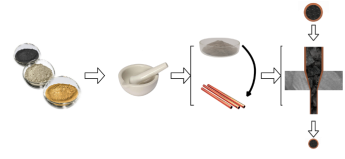

The technology maturity of this product is relatively high. It can not only directly use the production line of flux-cored welding wire that has been mass-produced, that is, strip method (which has been tested by an enterprise), but also use the round tube method in the initial stage or new product development (laboratory preparation, as shown in Figure 1). In recent years, more than 10 kinds of Fe-based, Cu-based shape memory alloys, 304 series stainless steel, wear-resistant modified 65Mn and other powder core wire materials have been prepared. The samples made by arc additive manufacturing equipment and laser additive manufacturing equipment have excellent performance and quality, and some products show new characteristics.

The powder core wire has 1 authorized international invention patent (Switzerland) (low function loss shape memory alloy micro-nano powder core wire for laser additive manufacturing and its preparation method) and 4 domestic invention patents (preparation method of ternary alloy powder core wire with specific filling rate prepared by circular tube method, preparation method of powder core wire for additive manufacturing with accurate composition obtained by adjusting powder particle size, etc.). 1 invention patent is in substantive examination stage. A relatively complete core patent group has been formed and is still continuing to improve.

Address: Fifth Floor, Block C of Tianrun Technology Building, No. 801 Changwuzhonglu, Wujin District, Changzhou, Jiangsu Province, China

Cell: 13813651639(Mrs Shi)

Email: 1320084251@qq.com

Web: www.czujs.cn