常州江苏大学工程技术研究院

Changzhou Engineering and Technology Institute of Jiangsu University

Welcome to Changzhou Engineering and Technology Institute of Jiangsu University!

Artificial muscle technology is a new type of flexible driving technology that converts various forms of energy input into mechanical energy output. There are some problems such as low output force and low energy. This technology breaks through the technical bottlenecks of artificial muscle such as low energy output, single output form and slow response speed, and realizes high energy output and fast drive of artificial muscle.

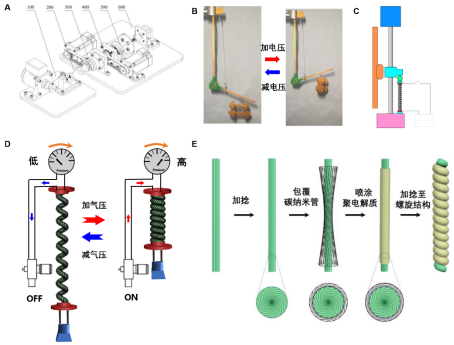

(1) Low cost (nylon 66), large stress, large strain electric heat artificial muscle and its large-scale production equipment

The automatic twisting collection device of fiber artificial muscle with independent property rights is developed and designed. The twisting stress and spring index can be adjusted, and the continuous production length is more than 1 km, promoting the automatic production of fiber artificial muscle. With a contraction rate of up to 20 percent and a stress rate of up to 26 MPa (93 times that of human muscle), the artificial muscle can be used in flexible robotic arms. An artificial muscle stress - strain test platform with dual - mode output was built.

(2) Pneumatic artificial muscles that drive both ways

Aiming at the problems of low response frequency and low energy efficiency of electric thermal artificial muscle, the team prepared pneumatic winding polymer artificial muscle with large shrinkage rate (40%), low driving pressure (0.15MPa) and high response frequency (5 Hz) by improving the structure of McKibben pneumatic artificial muscle. By adjusting the key preparation technology, the pneumatic winding artificial muscle with bidirectional drive can be prepared.

(3)Fast response sheath-core artificial muscle

Because the fibers naturally cool down slowly, electronic thermal artificial muscles cannot be used frequently. Our team developed a sheath-core artificial muscle, using the difference in sheath-core thermal conductivity to achieve a high frequency driving strain of 13% at 8 Hz. This technology lays a foundation for the application of bionic aircraft.

The team has about 5 years of research experience in fiber artificial muscle, and is committed to reducing the production cost of CNT fiber, developing new driving technology of CNT and polymer fiber artificial muscle, and developing intelligent soft robot driven by artificial muscle, etc. It has made important breakthroughs in driving principle, humanoid robot, complete set of preparation equipment, intelligent rehabilitation gloves, etc.

Address: Fifth Floor, Block C of Tianrun Technology Building, No. 801 Changwuzhonglu, Wujin District, Changzhou, Jiangsu Province, China

Cell: 13813651639(Mrs Shi)

Email: 1320084251@qq.com

Web: www.czujs.cn