常州江苏大学工程技术研究院

Changzhou Engineering and Technology Institute of Jiangsu University

Welcome to Changzhou Engineering and Technology Institute of Jiangsu University!

Technical field

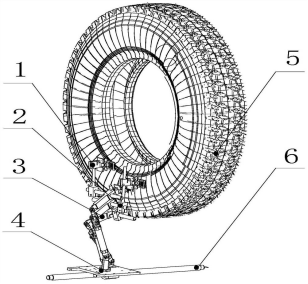

The invention relates to the field of tire manufacturing, in particular to a deburring device for the side of TB tire.

Background technique

With the growth of automobile production, the demand for tires is also increasing. However, based on the limitations of tire production technology, fetal hair will be generated in the tread and side of the tire, which will not only affect the appearance, increase the friction between the tire and the ground, but also produce noise when the car runs at high speed. If using traditional manual tire trimming machine, many manual operation, high labor intensity, low production efficiency, and unstable and uneven product quality can be seen, and the health of the operator may be badly influenced. Compared with traditional edging machine, automatic tire edging machine has its outstanding advantages, but there are also some problems. At present, there are automatic tire trimming machine products in the market. The trimming tool can carry out linear motion on the tread, so it can be very good for the removal of tire tread burr.

But TB tire is with large size, and its side hair removal is more difficult, so the tire side trimming quality can not be guaranteed.

The main reasons are as follows: ① The inner ring hair can not be completely removed. The tire hair of the inner ring on the side of the tire is close to the center of the tire and at the inner diameter of the tire side. The cutting tool moves toward the outer diameter of the tire during trimming. If the initial position of the blade is not accurate, the tire hair of the inner diameter of the blade will not be reached, so it can not be removed. ② Burr removal length is not uniform. Analysis of its causes: 1) tire side curve is irregular; 2) The side of the tire is printed with various specifications; that’s uneven; 3) Trimming tool is difficult to fit closely with tread; 4) It is difficult to evenly control the pressure of the tool on the tread. Based on the above objective situation of the side shape of the tire, it is difficult to ensure the uniformity of burr removal by the blade, resulting in substandard trimming quality.

A vehicle tire trimming machine is disclosed in Chinese patent 201020566465.0, which is used to trim the raw edge of the tire. The vehicle tire trimming machine comprises a frame host, a two-down trimming unit, a first up trimming unit, a second up trimming unit and a power drive device. In this patent, the trimming blade is connected by a counterweight and a chain to change the angle of the blade to the side of the tire. Different from the above patent, this invention is specialized for trimming the side of the tire, and the trimming tool head is pushed out by the cylinder, so as to ensure the contact force and fit degree between the blade and the tire.

A tire shaving machine disclosed in China patent 201320469643.1 includes tread razor, tread floating wheel, tread floating wheel, tread razor and other mechanisms. There is totally one side trimming tool, and the tool head is connected with the cylinder through a connecting rod. The lifting of the side trimming tool is dependent on the cylinder. Different from the above patent, this invention is specialized for trimming side tire, the tool head and the cylinder are directly connected through the nut, and the lifting of the side trimming tool is dependent on the motor lifting device. In this invention, there are four cutting tools, two symmetrical on the left and right, which can greatly shorten the trimming time, improve production efficiency.

The invention has the advantages of:

In order to ensure that the contact area between the blade and the tire is large enough, it is necessary that the adjacent blade can achieve seamless splicing, so the three independent blades on the three trimming tool mechanism in the tool assembly on one side are connected to the edge, that is, the three small blades are combined into a large blade. The advantages of this design are: 1) all three blades can contact with the tire to ensure that the contact area is large enough; 2) The blade can adapt to the shape of the side curve of the tire to ensure the removal effect of burr; 3) Three knives integrated into one knife can realize the flexible contact between the blade and the tire, ensuring the fit degree between the blade and the tire tread, so as to improve the trimming quality of the tire. Placing two groups of tool assemblies CAN shorten trimming time and improve trimming efficiency; adjusting the angle between the tool and the tread CAN control the length of the tire hair; changing the position of the tool assembly through the movement of the ball screw platform CAN trim different sizes of tires.

Address: Fifth Floor, Block C of Tianrun Technology Building, No. 801 Changwuzhonglu, Wujin District, Changzhou, Jiangsu Province, China

Cell: 13813651639(Mrs Shi)

Email: 1320084251@qq.com

Web: www.czujs.cn