常州江苏大学工程技术研究院

Changzhou Engineering and Technology Institute of Jiangsu University

Welcome to Changzhou Engineering and Technology Institute of Jiangsu University!

Technical field

The invention relates to the application technical field of laser processing, in particular to a laser phase transformation hardening method and a processing device for raceway of variable rotor/yaw bearing rings, and is suitable for heat treatment of raceway surface of large bearings.

Technical background

The working environment of wind turbine is harsh, so the vibration resistance and fatigue resistance are required to be higher. In order to improve the service life of bearings, heat treatment is needed on the surface of bearing ring raceway during processing to improve its corrosion resistance and vibration resistance. Variable paddle/yaw bearing ring is generally manufactured by 42CrMo. Other materials with comparable or better performance can also be used, and the surface hardening hardness of the ring raceway shall be no less than 55HRC, and the surface hardening layer depth of the raceway shall be no less than 3mm.

Traditional heat treatment process can obtain high hardness of martensite through normalizing, annealing, quenching in tempering, and after tempering the vibration resistance and anti-fatigue performance can greatly improve. However, due to the instability of temperature in the processing, the workpiece in the induction quenching stage often has soft belts due to incomplete quenching. The size of variable paddle/yaw bearing ring is generally more than two meters. It is difficult to process some parts, and the ring wall is thin. Therefore, the workpiece will produce thermal deformation due to high temperature in the heat treatment process. Therefore, the workpiece generally needs to be processed after tempering, and in the process of tempering cracks may also be produced, leading to scrap.

With the progress of science and technology, laser quenching gradually began to be widely used in machinery industry. Compared with traditional quenching, laser quenching has high energy density, fast cooling speed, no need for cooling medium, uniform quenching layer, high hardness (1 ~ 3HRC higher than traditional quenching), small workpiece deformation, easy to control heating layer depth and heating track , easy to realize automation. Therefore, in many fields, laser quenching is gradually replacing the traditional quenching. Laser quenching is also widely used in the phase change hardening of wind turbine bearing rings. Laser quenching can realize the partial processing of bearing ball and ring raceway, and the quenched workpiece does not need to carry on further finishing, which improves its performance and saves the processing.

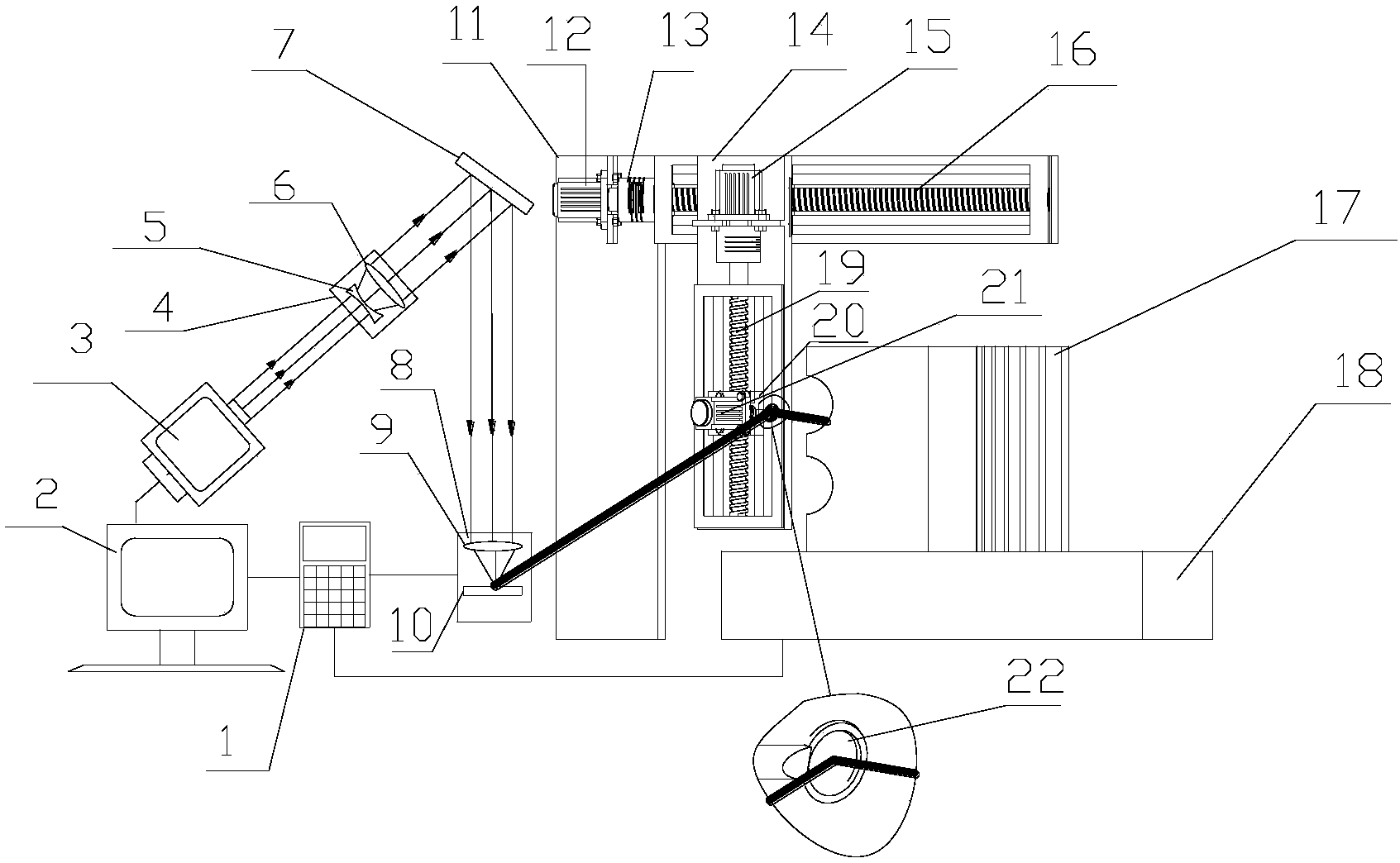

The evenly distributed hardening layer along the raceway surface is the ideal shape of the ring hardening layer. In the current domestic laser heat treatment process, laser is always directed at the workpiece at a constant angle, and the hardening layer is the deepest along the laser direction. For the straight workpiece, laser can always be perpendicular to the plane directing at the workpiece, and the hardening layer is evenly distributed along the plane. For the irregular curved surface, the laser cannot always be perpendicular to the surface, so in the laser phase change hardening process of variable paddle/yaw bearings, the depth of the hardening layer along the raceway surface is often inconsistent. In the invention, the processing angle of the laser on the raceway of the ring can be adjusted according to the bearing of different sizes, so as to achieve the maximum processing depth and obtain the uniformly distributed hardening layer, and improve the service life of bearings.

Beneficial effects of the invention:

1. After laser phase transformation hardening process by laser beam on the surface of the vertical raceway, the depth of the hardened layer is significantly increased, and the maximum depth of the hardened layer can reach 6.5mm. The uniform and stable dislocation, and the refined grain on the surface and the subsurface of the raceway effectively improve the contact strength and fatigue resistance of the bearing raceway, and also improve the wear and corrosion resistance of the bearing raceway.

2. The support frame is provided with a tilt table of 45 degrees, and different angles of the tilt table can be changed according to the working environment and conditions, which can realize the phase change hardening processing of raceway.

3. The cantilever beam and the support frame are equipped with ball screw, which can process the raceway of bearing rings of different sizes. The device can be used to carry out phase transformation hardening process for different types of rings, and has universal applicability for large bearing rings with a diameter of more than two meters.

Address: Fifth Floor, Block C of Tianrun Technology Building, No. 801 Changwuzhonglu, Wujin District, Changzhou, Jiangsu Province, China

Cell: 13813651639(Mrs Shi)

Email: 1320084251@qq.com

Web: www.czujs.cn