常州江苏大学工程技术研究院

Changzhou Engineering and Technology Institute of Jiangsu University

Welcome to Changzhou Engineering and Technology Institute of Jiangsu University!

Technical field

The invention belongs to the technical field of materials, in particular to a method for indirectly detecting the plastic deformation ability of a deformed aluminum alloy and its application.

Background technique

The plastic deformation ability of materials is the main aspect of material properties. At present, the tensile properties of materials are mainly obtained through tensile experiments, and the plastic deformation ability of materials is mainly characterized by elongation and section shrinkage. At this time, it is necessary to process the tensile sample that meets the standard, and it is required to provide a certain size and a certain quality of the material to be tested, which needs to consume a relatively large amount of raw material. The tensile test is a destructive test, and it is easy to cause processing stress in the sample during processing, and the error of the experimental results is high. At the same time, due to the differences within the material, it is inevitable that there will be errors in the detection part in practical application, which puts forward higher requirements for the experimental conditions and material sampling. Therefore, there are many shortcomings in the standard tensile test used to measure the plastic deformation capacity of materials in the prior art. It is necessary to invent a new method to detect the plastic deformation capacity of materials with the development of the prior art.

Electron paramagnetic resonance (EPR) spectroscopy is one of the means of testing the properties of modern new materials, and it is a spectral method for detecting samples containing unpaired electrons. The phenomenon of EPR was first discovered by Soviet scientist Е K. Zavoysky in 1944 from paramagnetic salts. At first, EPR technology was mainly used to study the electronic structure, crystal structure, dipole moment and molecular structure of some complex atoms, and was mainly used in the field of microstructure research. After literature search, there was no report on the application of EPR spectroscopy to determine the mechanical properties of metal materials. Because of the relationship between the properties of metal materials and the structure of materials, it is worth trying to invent a method to detect the mechanical properties of materials through the study of the microstructure of materials.

Content of invention

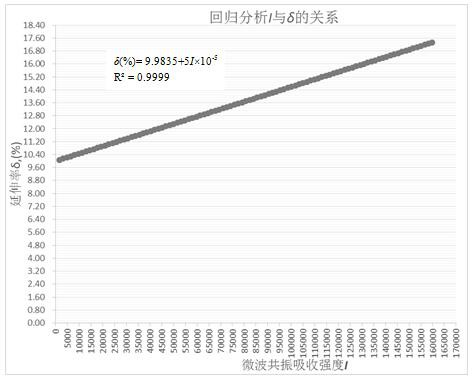

The purpose of the invention is to provide a simple, efficient and high accuracy method for indirect determination of the plastic deformation ability of deformed aluminum alloy by studying the connection between the microstructure of the material and the macroscopic mechanical properties through a modern new method of analysis and detection, so as to overcome the shortcomings of the standard tensile experiment of the prior art, which includes: it is difficult to solve the problems of destructive experiment, large error and low measurement success rate.

Compared with the prior art, the beneficial effects of the invention are as follows:

(1) The measurement method of the invention belongs to non-destructive testing and does not belong to destructive experiment. Compared with the tensile test measurement of the prior art, the sample is completely destroyed because the tensile test needs to break the sample, while the invention only needs a small area of clean and smooth metal surface, which does not destroy the sample and reduces the consumption of materials.

(2) Because the sample is not destroyed by the invention, the experimental error can be eliminated by repeated measurement. The prior art adopts tensile experiment, which can only be measured once, with high experimental contingency, large error and high experimental failure rate, and multiple samples need to be processed during multiple measurements.

(3) The invention is based on electronic paramagnetic resonance spectroscopy detection of metal materials, and has stable data, high reliability, and simple sample processing. Sample processing will not cause processing stress of the material, and overcomes the processing stress generated by cutting and grinding during sample processing in present tensile experiment. The processing stress has a significant impact on the experimental results. The invention overcomes the problem that the prior art is difficult to overcome by the tensile test.

Address: Fifth Floor, Block C of Tianrun Technology Building, No. 801 Changwuzhonglu, Wujin District, Changzhou, Jiangsu Province, China

Cell: 13813651639(Mrs Shi)

Email: 1320084251@qq.com

Web: www.czujs.cn