常州江苏大学工程技术研究院

Changzhou Engineering and Technology Institute of Jiangsu University

Welcome to Changzhou Engineering and Technology Institute of Jiangsu University!

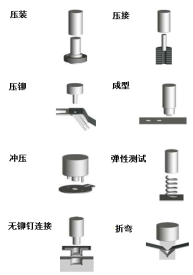

In the process of parts production, assembly by pressing machine is a common means, such as shaft assembly, pin assembly, etc. For traditional mechanical, hydraulic or gas-hydraulic force-enhancing press-fitting equipment, the press-fitting force and the press-fitting displacement cannot be accurately controlled.The determination of the press-fitting result is realized by monitoring the pressure of several specific displacements, which cannot display the pressure-displacement curve in real time, and can not fully reflect the change of pressure-displacement during the press-fitting process. This may lead to unqualified products flowing into the market. In auto parts, electronics, home appliances and other industries, the needs of enterprises for high-precision assembly have been unable to meet.

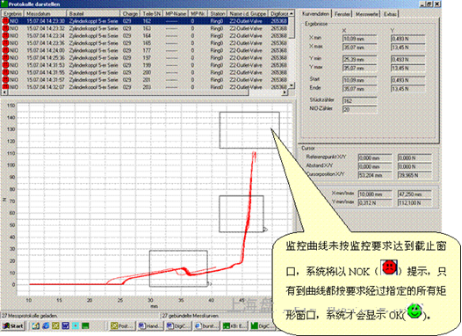

The technology provides an intelligent servo press assembly system, whose core is to use AC servo motor as power source, with precision planetary gear reducer to drive the lead screw to achieve product press assembly. It is an integrated system which integrates the press assembly process execution (electric servo pressure cylinder) device, the electric servo drive device and the press assembly process control and detection device, specially used for the press assembly operation of mechanical products. In addition to the servo pressing machine, intelligent servo pressing system is also equipped with a special measurement and control software system, without additional configuration of expensive special pressure - displacement monitor. This not only can produce accurate pressing displacement and pressing force, but also can realize the online monitoring and evaluation of the pressing process, greatly improving the qualified rate of products and reducing cost, which is the future development direction of the pressing machine.

This technology has been authorized by the invention patent, patent number: 201510885376.X

Address: Fifth Floor, Block C of Tianrun Technology Building, No. 801 Changwuzhonglu, Wujin District, Changzhou, Jiangsu Province, China

Cell: 13813651639(Mrs Shi)

Email: 1320084251@qq.com

Web: www.czujs.cn