常州江苏大学工程技术研究院

Changzhou Engineering and Technology Institute of Jiangsu University

Welcome to Changzhou Engineering and Technology Institute of Jiangsu University!

The invention relates to the technical field of sludge drying, and more specifically to an integrated solar sludge drying system utilizing the combined action of a solar collector and a solar house. The drying system comprises a multifunctional solar house, a heat conduction tank, a solar collector, a fan, a solar air collector, a sludge feeder, a shaftless spiral drier and a mud storage tank. Compared with the solar sludge drying device with the same sludge treatment capacity, the area of the solar sludge drying device is further reduced, and the sludge drying time is shortened compared with the traditional single use of solar sludge drying house. This system can realize the short cycle of sludge drying production and low energy consumption, and is easy to implement. With significant social and economic benefits, it can be widely used in sludge drying treatment of sewage treatment plant .

Technical field

The invention relates to the technical field of sludge drying, and more specifically to an integrated solar sludge drying system utilizing the combined action of a solar collector and a solar house.

Background technique

With the continuous development of environmental protection business, a large number of new sewage treatment plants across the country are built, but sewage treatment plants will produce a large number of by-products - sludge, producing secondary pollution if treating improperly. According to statistics, the total sludge produced in China by the end of 2010 amounts to about 30 million tons, so sludge harmless and resource treatment is becoming more prominent.

The water content of dehydrated sludge after being treated by sewage treatment plants is still up to 75%~80%. A huge volume is also a problem, and there is no unified mode for the disposal of sludge: most cities still choose the method of direct waste or landfill, and some areas choose to use the sludge drying for sludge treatment. The traditional sludge drying method is a process of high energy consumption and high investment. The high treatment cost and high energy consumption are the main problems restricting sludge treatment, so the municipal sewage sludge can not be treated effectively for a long time.

According to the search of existing invention patents, there are also solar drying devices for sludge, such as activated sludge solar drying devices (patent No. : 200710181080.5). It uses solar greenhouse for turning and composting, but this method has a long drying cycle. Therefore, it is of great research value to explore an integrated solar sludge drying system with large drying capacity and short drying cycle and low energy consumption.

Content of invention

Aiming at the deficiency of the prior art, the invention provides an integrated solar sludge drying system.

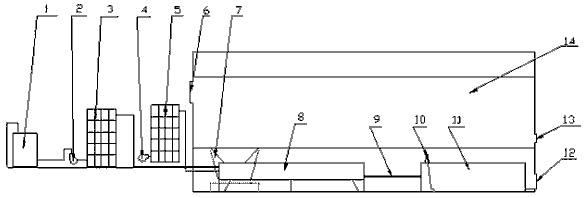

The integrated solar sludge drying system comprises a multifunctional solar house, a heat conduction tank, a solar collector, a fan, a solar air collector, a sludge feeder, a shaftless spiral drier and a mud storage tank. The heat conduction tank is connected with the solar collector through the oil pump; the fan is connected with the solar air collector; a mud storage pond is arranged on the east side of the multifunctional solar house, and a plow and harrow device which can continuously turn over the sludge is installed on the mud storage pond. In the northwest side of the multifunctional solar room, three three-dimensional triangular arrangement of the axial spiral dryer is arranged; in the multifunctional solar room is provided with ventilation equipment on the west wall, and in the multifunctional solar room is provided with an air exchange on the east wall. The solar house sludge outlet is arranged at the bottom of the east side of the solar house. Each shaftless spiral dryer comprises a shaftless spiral dryer cavity, a hot oil pipe, a hot oil pipe cavity, an explosion-proof motor and a shaftless screw.

The shaftless spiral rod is installed in the shaftless spiral dryer cavity and connected with the explosion-proof motor, which has the function of stirring and conveying sludge. The hot tubing cavity is close to the body wall of the shaftless spiral dryer. The hot oil pipe is arranged in the hot oil pipe cavity and welded on the body wall of the shaftless spiral dryer. The hot air inlet is arranged in the upper part of the cavity of the shaftless spiral dryer and is connected with the solar air collector. The hot oil inlet and outlet are arranged under the hot air inlet and are respectively connected with the solar collector and the hot oil pipe. The sludge inlet is near the explosion-proof motor at the top of the shaftless spiral dryer chamber; it is installed in the multifunctional solar chamber and connected with the shaftless spiral dryer chamber connected with the mud storage tank through the belt conveyor. The three shafeless spiral dryers arranged in triangular-dimensional arrangement are connected end to end, and the sludge circulation mouth of each shafeless spiral dryers is connected with the sludge inlet of another shafeless spiral dryers.

The sludge circulation port is arranged at the bottom of the shafeless spiral dryer chamber away from the explosion-proof motor. The sludge outlet of the dryer is arranged at the lower side of the back end of the cavity of the shafeless spiral dryer connected with the mud storage tank through the belt conveyor, and a sludge circulation mouth baffle is arranged in front of the sludge circulation mouth. The slide block installed on the upper surface of the hot oil pipe cavity drives the sludge circulating mouth baffle to move. When the moisture content of the sludge drops to the set moisture content, the sludge circulation mouth baffle and the belt conveyor start to operate. The sludge circulation mouth baffle will block the sludge circulation mouth, and the belt conveyor will transport the sludge in the dryer from the sludge outlet of the dryer to the mud storage tank.

The integrated solar sludge drying system is characterized in that the lower half wall and the whole north wall of the multifunctional solar house use thermal insulation wall, and the upper half wall and the roof use heat-absorbing glass. The plough and harrow device is installed above the mud storage pool, the same with a beam made of steel sheet and a number of harrow teeth welded on the beam. The length of the harrow teeth and the depth of the mud storage pool match together, showing a semicircle shape, and they inclined welding with the beam at a certain angle. The plough and harrow device in the mud storage pool move along the east-west direction through the block installed in the mud storage pool on both sides of the sliding block, which plays the role of continuously turning over the sludge in the mud storage tank.

Compared with the prior art, the beneficial effects of the invention are:

(1) The solar energy is used to dry the sludge, which greatly reduces the energy consumption in the process of sludge drying;

(2) The triangulation arrangement of shafeless spiral dryer increases the residence time of sludge in the dryer and reduces the footprint of the dryer;

(3) The integrated design of the dryer and the solar house effectively reduces the land area of the sludge drying system and improves the drying environment temperature of the dryer sludge, which is conducive to the process of sludge drying;

(4) The design of the heat transport tube of the shaftless spiral dryer can maximize the using efficiency of the heat provided by solar energy and improve the drying efficiency of the sludge.

Address: Fifth Floor, Block C of Tianrun Technology Building, No. 801 Changwuzhonglu, Wujin District, Changzhou, Jiangsu Province, China

Cell: 13813651639(Mrs Shi)

Email: 1320084251@qq.com

Web: www.czujs.cn