常州江苏大学工程技术研究院

Changzhou Engineering and Technology Institute of Jiangsu University

Welcome to Changzhou Engineering and Technology Institute of Jiangsu University!

Background technique

Lithium-ion batteries have been widely used because of their advantages such as high energy density, good cycling performance, environmental protection and no pollution, and have become the preferred power battery for electric vehicles and hybrid electric vehicles. With the gradual development of electric vehicles and hybrid electric vehicles, higher requirements have been put forward for the performance of lithium-ion batteries, which need to have high energy density, good safety, low temperature performance and other advantages.

At present, traditional lithium-ion batteries, such as lithium manganese acid battery, lithium iron phosphate battery and ternary battery, are difficult to meet the requirements of electric vehicles and hybrid electric vehicles due to their respective defects. For example, the conventional lithium-ion batteries mentioned above are difficult to meet the density requirements of lithium-ion batteries for electric vehicles due to their low specific energy (generally less than 120Wh/Kg). Therefore, it is necessary to develop new lithium-ion batteries with high energy density, good cycle performance and good safety performance.

The lithium-ion battery prepared by LiNi0.5Mn1.5O4 attracted people's attention by high working voltage (4.7V) and high energy density (> 150Wh/Kg). However, in the process of using lithium ion batteries prepared by this material, people found that the decomposition of ordinary electrolyte is more serious due to its high charging and discharging voltage, so serious flatness phenomenon can be seen,also affecting its application and development.

Content of invention

The purpose of the invention is to solve the flatulence problem of the existing lithium ion battery and to provide an electrolyte which can effectively prevent the flatulence of the lithium ion battery in the process of charging and discharging.

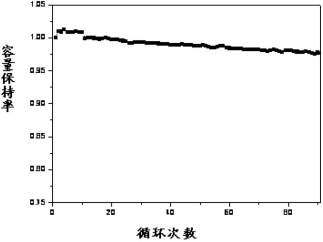

The present technical scheme is a kind of lithium ion battery electrolyte, including solvent, lithium salt and additives. The sum of solvent and additive mass is 100%, the sum of the quality of the mass fraction of the solvent for 90 95%, the lithium salt of amount of substance concentration of electrolyte is 0.9 1.4 mol/L, and the additive is one or both of ethyl sulfate and acrylic sulfite.

Among them, the electrolyte for lithium ion battery of the invention can be obtained by directly mixing various raw materials.

Address: Fifth Floor, Block C of Tianrun Technology Building, No. 801 Changwuzhonglu, Wujin District, Changzhou, Jiangsu Province, China

Cell: 13813651639(Mrs Shi)

Email: 1320084251@qq.com

Web: www.czujs.cn