常州江苏大学工程技术研究院

Changzhou Engineering and Technology Institute of Jiangsu University

Welcome to Changzhou Engineering and Technology Institute of Jiangsu University!

Maturity:

The global supercapacitor industry is developing rapidly. It is estimated that by 2020, the market size in China will increase to 11 billion yuan, and the European and American markets will increase to 4.5 billion dollars. However, there are still many technical problems in its application, especially the development of new high-capacity electrodes, which has become the key bottleneck to further promote the industrialization of supercapacitors.

Technical advancement:

According to the Industrial Research Center of China Graphene Industry Technology Innovation Strategic Alliance, the development and application project of graphene in supercapacitors is expected to achieve large-scale commercialization in 3-5 years. According to the statistics of Industrial Research Center of China Graphene Industry Technology Innovation Strategic Alliance, the global market scale of graphene supercapacitors will reach 4.18 billion US dollars by 2020, which will indirectly promote the market scale of new energy vehicles, rail transit, power storage, aerospace and other related industry chains to reach more than 50 billion US dollars. Therefore, the promotion and application of graphene-based supercapacitors will have great industrialization prospects.

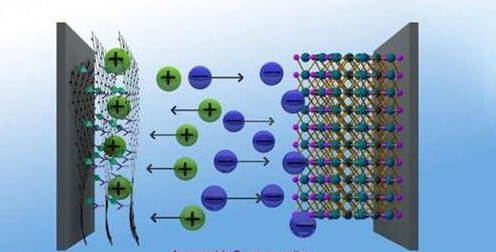

Compared with traditional capacitors and batteries, supercapacitors have a series of advantages such as short charging and discharging time, high power density, good temperature characteristics, long cycle life, simple structure and green environmental protection. They play a huge role in solving environmental pollution and energy shortage, and developed countries have included them in their national development strategies. In 2005, "Research and preparation technology of key materials for supercapacitors" was listed in the National Program for Medium - and Long-term Scientific and Technological Development (2006-2020), considering as one of the leading technologies in the field of energy. The 13th Five-Year Plan includes super capacitor in the national special support key projects and a key product of emerging industries.

Technical advantages:

(1) Develop a new vacuum preparation technology for large-area graphene composite films: aiming at the requirements of large area, high capacity and high stability of supercapacitor electrode; solving the contradiction between extremely high porosity and high flexibility in vacuum pressed film technology; breaking through key technology of preparing large-area and high-quality graphene based composite flexible film electrode material system.

(2) Master the core technology of the design and control of the vacuum pressure film device for the preparation of graphene composite electrode, develop large-area high-performance graphene composite film electrode products, promote the technological breakthrough of supercapacitors, provide technical and product support for high-energy density supercapacitors, and solve the problem that China's high-end high-power supercapacitors are relatively backward and rely on imports, break the technical barriers of foreign related products, realize the localization of high-end high-power supercapacitors, and have independent intellectual property rights.

Intellectual property situation:

At present, the relevant authorized national invention patents.

Expected goal:

Through cooperation with enterprises, the small vacuum film pressing device used in the laboratory is scaled up, and the vacuum film pressing device with controllable pressure which can realize rapid solid-liquid separation is developed. The macro preparation devices mainly include: vacuum drainage power system, powder mixing device, controllable vacuum pressure regulation system, environmental temperature and humidity monitoring system and drying and storage devices of thin film electrode materials, so as to achieve large area and macro preparation of thin film electrode materials.

Achievement index:

(1) Research and development of a vacuum film pressing device capable of macroscopically preparing large-area graphene/multi-layer metal oxide hollow ball composite film electrode materials with controllable pressure.

(2) Open hole design of graphene is carried out to prepare high-capacity graphene powder material, and its capacity was increased to more than 800 F g-1.

(3) In the process of vacuum film pressing, we adjust the content of active substances added in the multi-layer metal oxide hollow ball, determine the optimal ratio of powder, and achieve the volume capacity of graphene composite film more than 1200 F cm-3.

(4) We use the prepared high-capacity composite thin film electrode material to assemble high-performance supercapacitor device, whose volume energy density is more than 80 Wh L-1. Capacity retention rate can reach more than 90% after 10000 cycles and there is good structural stability.

(5) Proprietary technology: acceptance of 3-6 invention patents; publishing 4-10 Chinese core journals or three major search papers.

Address: Fifth Floor, Block C of Tianrun Technology Building, No. 801 Changwuzhonglu, Wujin District, Changzhou, Jiangsu Province, China

Cell: 13813651639(Mrs Shi)

Email: 1320084251@qq.com

Web: www.czujs.cn