Fuel cell engine research

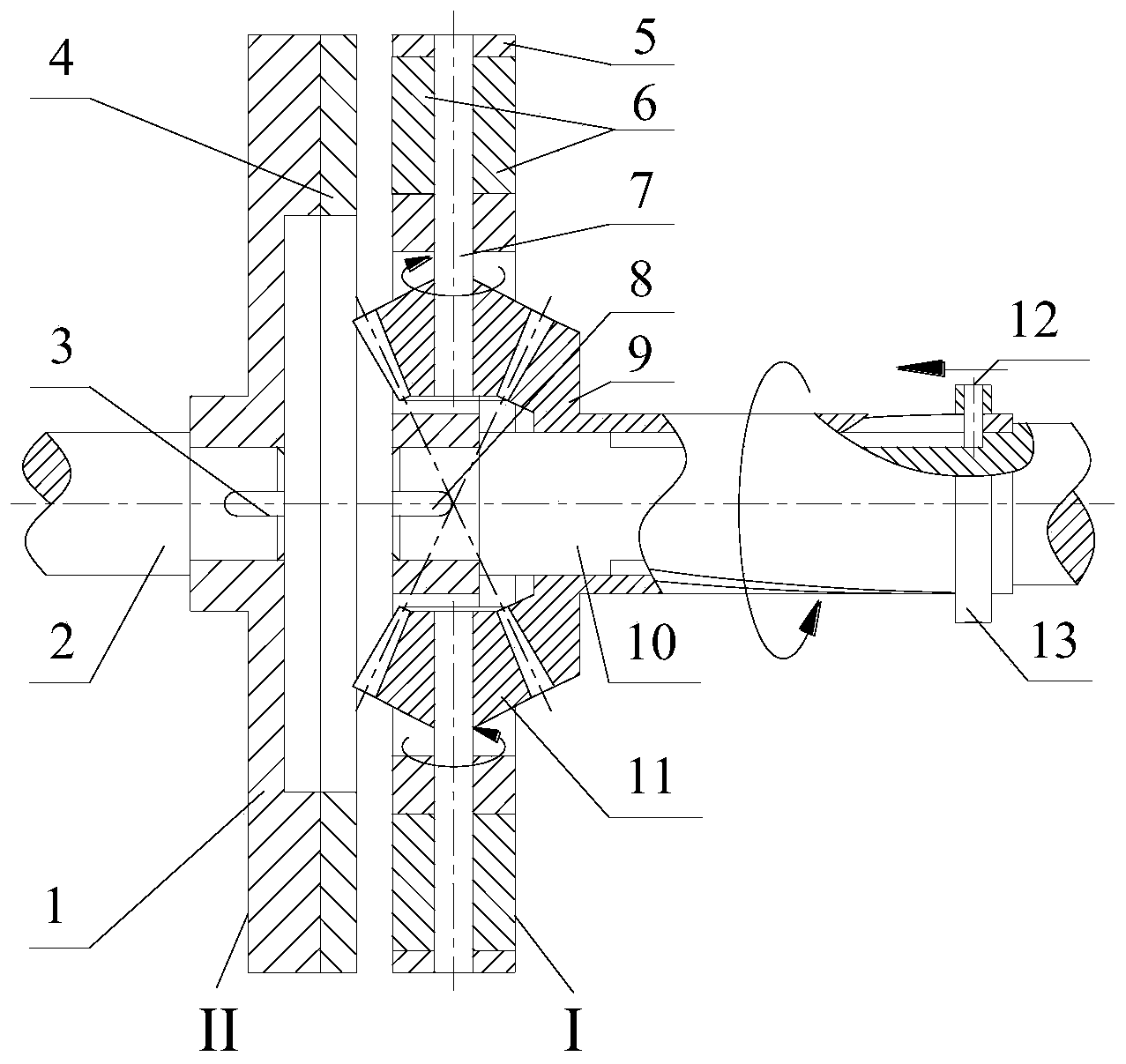

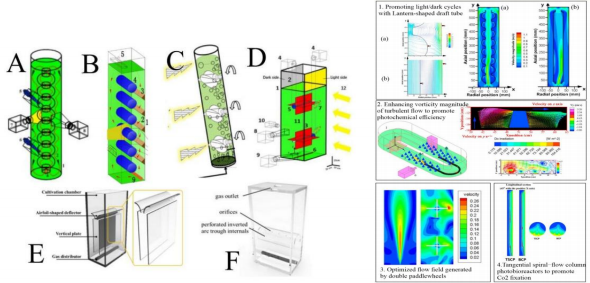

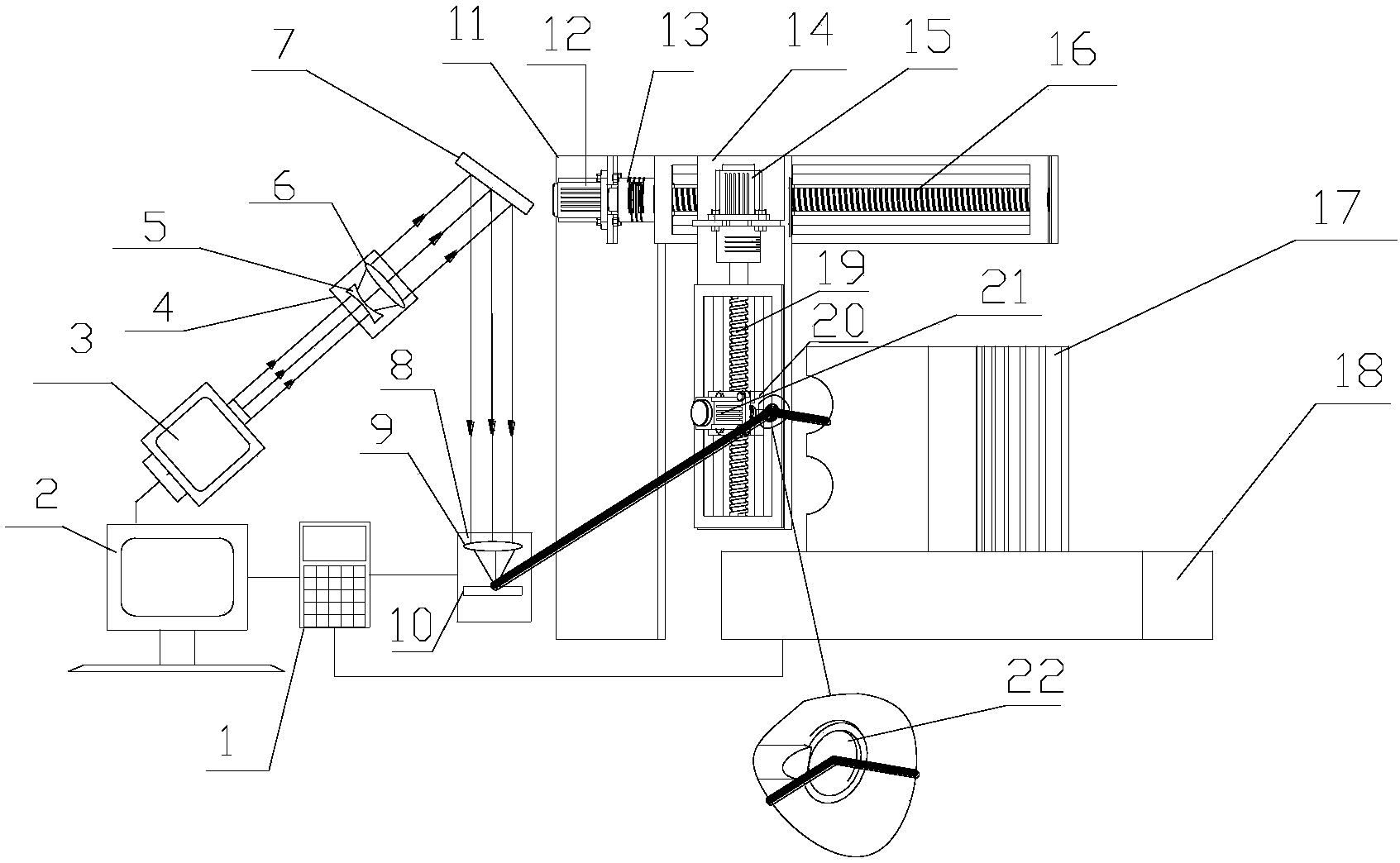

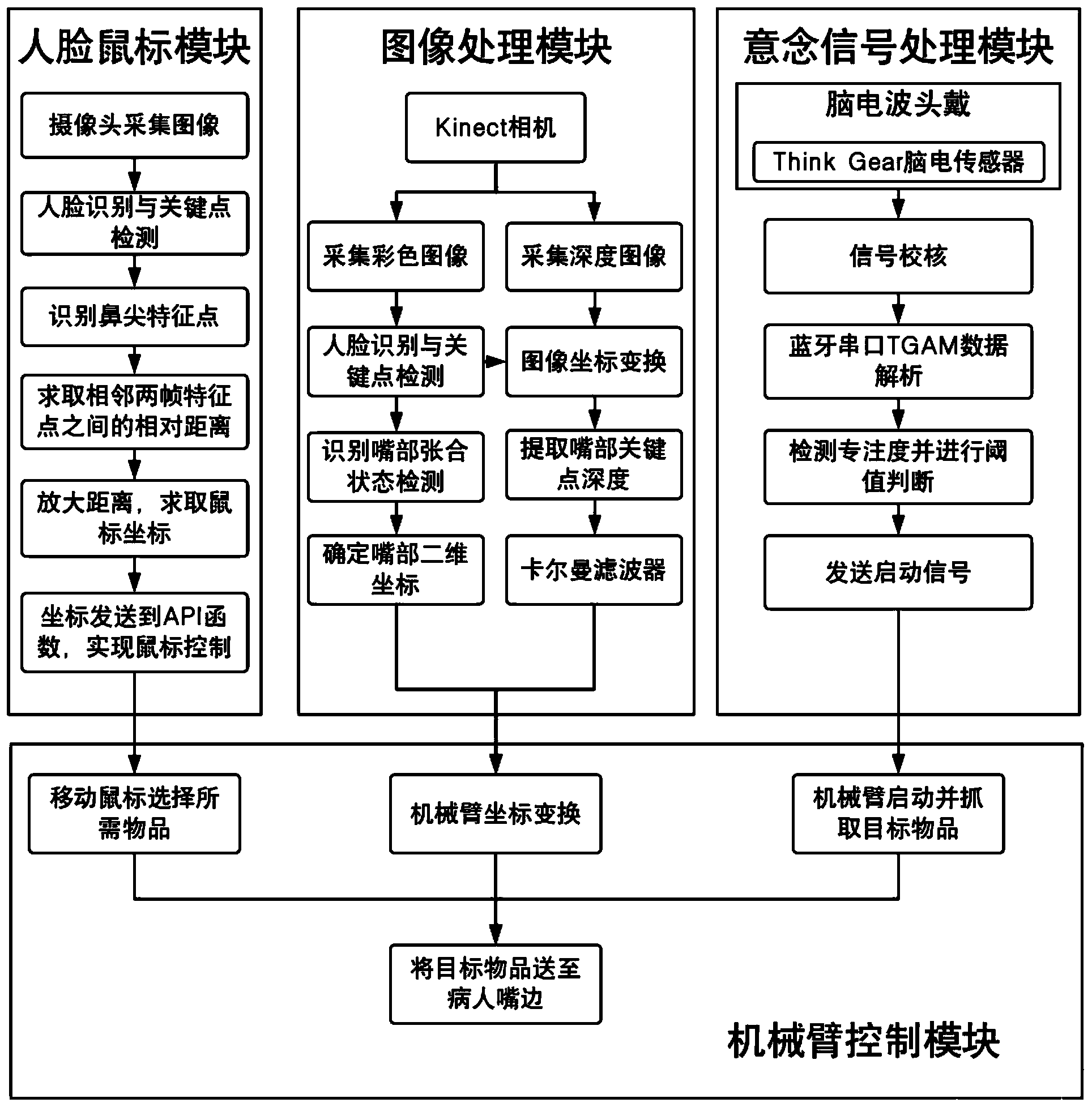

1 Construction OverviewThe development of hydrogen fuel cell vehicle is a major strategic demand of dual carbonHydrogen fuel cell vehicle: zero emission, fast fuel filling, good low temperature performance, long driving range, etc.However, there are still shortcomings in energy density, safety and efficiency of fuel cell vehicles.To tackle key technologies of fuel cell vehicles and promote the application of fuel cell vehicles is an inevitable choice to implement the national strategy and national plan.Fuel cell engine research instituteBased on the national two-carbon strategy, the Fuel Cell Engine Research Institute of Jiangsu University has made full use of integrated resources to form a research institution with basic research, high-tech innovation, talents and authoritative evaluation functions. Aiming at the vehicle scale fuel cell engine and through the research and development of new key materials with high performance and long life, key component technology breakthrough, intelligent integrated technology innovation research, we break the development bottleneck, vigorously develop and obtain fuel cell engine complete machine and core component technology with independent intellectual property rights, so that the institute becomes an effective channel for the transformation of research results into application. It plays the role of an important source and strong support platform for the independent innovation of industrial technology, and forms a research and development group of domestic new energy power system and a training base for related professional and technical personnel.As a member of the fuel cell Engine Sub-committee of China Internal Combustion Engine Society, the Institute is an important research and development force in the field of advanced new energy vehicles in our province. It undertakes and participates in the national, various ministries and local longitudinal research projects, and carries out extensive cooperation with scientific research institutions, universities and enterprises in our province.At present, in the institute there are 5 full-time teachers, 6 associate professors, 7 lecturers, 3 industry professors, 5 full-time doctoral students and more than 20 master students.Scientific research conditions2. Basic ResearchMacroscopic scale numerical calculation method -- VOF model developmentNumerical calculation method of mesoscopic scale: Development of lattice Boltzmann modelResearch Direction 1- Fuel cell efficient water and gas transport managementIn order to explore the wetting state of the micro-pore surface on the fuel cell runner surface and optimize the shape parameters of the micro-pore surface, a two-dimensional lattice Boltzmann pseudo-potential multiphase flow model was established to investigate the influence of shape on wetting behavior.In order to improve the drainage performance of proton exchange membrane fuel cell (PEMFC), a three-dimensional numerical study of water removal in the flow channel of microstructured PEMFC was carried out. The influence of microstructure shape parameters (height, radius and spacing) was investigated.Research Direction 2- Fuel cell cold start mechanismIn order to explore the melting process of perforated gas diffusion layer and the effective and efficient GDL structure to improve the performance of ice melting, a three-dimensional ice melting model was established based on the enthalpy lattice Boltzmann method. Modified bending boundary conditions are used to account for complex carbon fiber surfaces. The influence of hole shape parameters on ice melting was studied.A three-dimensional model was established based on lattice Boltzmann method (LBM) to study the ice melting process in the gas diffusion layer of PEMFC. A single point second order curved boundary condition is adopted. The effects of carbon fiber quantity, carbon fiber quantity increasing slope and carbon fiber diameter on ice melting were studied.Research Direction 3- Hydrogen production from methanol reformingThe tubular methanol steam reformer and the self-heating plate reformer based on fractal theory were designed and developed respectively, and catalysts were loaded by packed bed and impregnation method to study the performance of methanol steam reformer.In order to investigate the influence of fractal structure on the heat and mass transfer process of methanol reforming reaction, a three-dimensional numerical model of methanol steam reforming reaction was established based on the three-rate reaction mechanism, and the influence of characteristic parameters of fractal structure on the heat and mass transfer process of the reactor was discussed.Research Direction 4- Electric hybrid energy managementTaking fuel cell and power cell mixing degree as the research object, the coupling mechanism of static mixing degree and dynamic mixing degree was studied to obtain the optimal vehicle design parameters.The output feedback of continuous dynamic input excitation was obtained by bench tests of the system and components, and the deviation between the real model and the simulation model was obtained by Sobol method of global sensitivity analysis to form a high-precision simulation model.In the framework of MPC model prediction algorithm, LSTM long and short term memory artificial neural network was used for speed prediction, and DDPG depth deterministic strategy gradient algorithm was used for energy management and control.Research Direction 5- Fuel cell vehicle developmentJointly develop fuel cell vehicle electronic control platform with domestic well-known enterprises, and conduct prototype research and development and testing based on mature platform technology.The developed energy management control strategy was verified by HIL hardware-in-the-loop test and vehicle test, and the vehicle development process was closed.Research Direction 6- Liquid hydrogen storage and transportation technology and applicationTo develop high-safety and long-life liquid hydrogen systems for vehicle use, break through key technologies such as short vacuum life of liquid hydrogen bottles and high safety requirements for complete equipment, and promote the industrialization of liquid hydrogen equipment for vehicle use.Design and develop hydrogen fuel cell vehicle circulating water bath double helix shell carburetor, and optimize the structural parameters to determine the best circulating water flow under different working conditions, compared with the traditional carburetor vaporization efficiency is significantly improved.Design and develop liquid hydrogen cold energy utilization system, make full use of the cold energy of liquid hydrogen in the process of vaporization, greatly improve the utilization efficiency of liquid hydrogen as an automobile energy, and realize energy recycling.The power battery subsystem uses the combined cycle method which combines the direct expansion method and Rankine cycle method to exchange heat between the cold energy of liquid hydrogen vaporization and the waste heat of lithium battery and motor, so as to realize the combined power generation of cold energy and heat energy.3. Engineering DevelopmentCooperative partnerWork together to tackle key problems in the whole industry chain -- establish a "fuel cell vehicle demonstration and application consortium" to ensure orderly research and development of a new generation of fuel cell vehicles through efficient upstream and downstream linkage of the industry chain of vehicle enterprises, fuel cell system enterprises, operators, users and hydrogenation stations.Typical case - Ejector design optimizationAccording to the requirements of enterprises, the ejector components of fuel cell hydrogen circulation system were optimized. After optimization, the ejection ratio is over 3, well meeting the requirements of enterprises.Typical case - Design optimization of hydrogen separatorAccording to the requirements of enterprises, the baffle type hydrogen separator of fuel cell hydrogen circulation system was designed and optimized. The water separation efficiency of the optimized hydrogen separator can reach 90%, meeting the needs of enterprises.Typical case - Hydrogen supply valve group developmentThe joint development of the fuel cell hydrogen supply valve suite, including hydrogen stop valve SOV, hydrogen injection proportional valve HGI, ejector JP, pressure limiting valve PLV-G and pressure sensor; it reduces the volume of the hydrogen supply system, simplifies the gas path structure, and improves the sealing performance.

View more